VMA Case Study: FAA Radar Cabinets

- Read more about VMA Case Study: FAA Radar Cabinets

- Log in to post comments

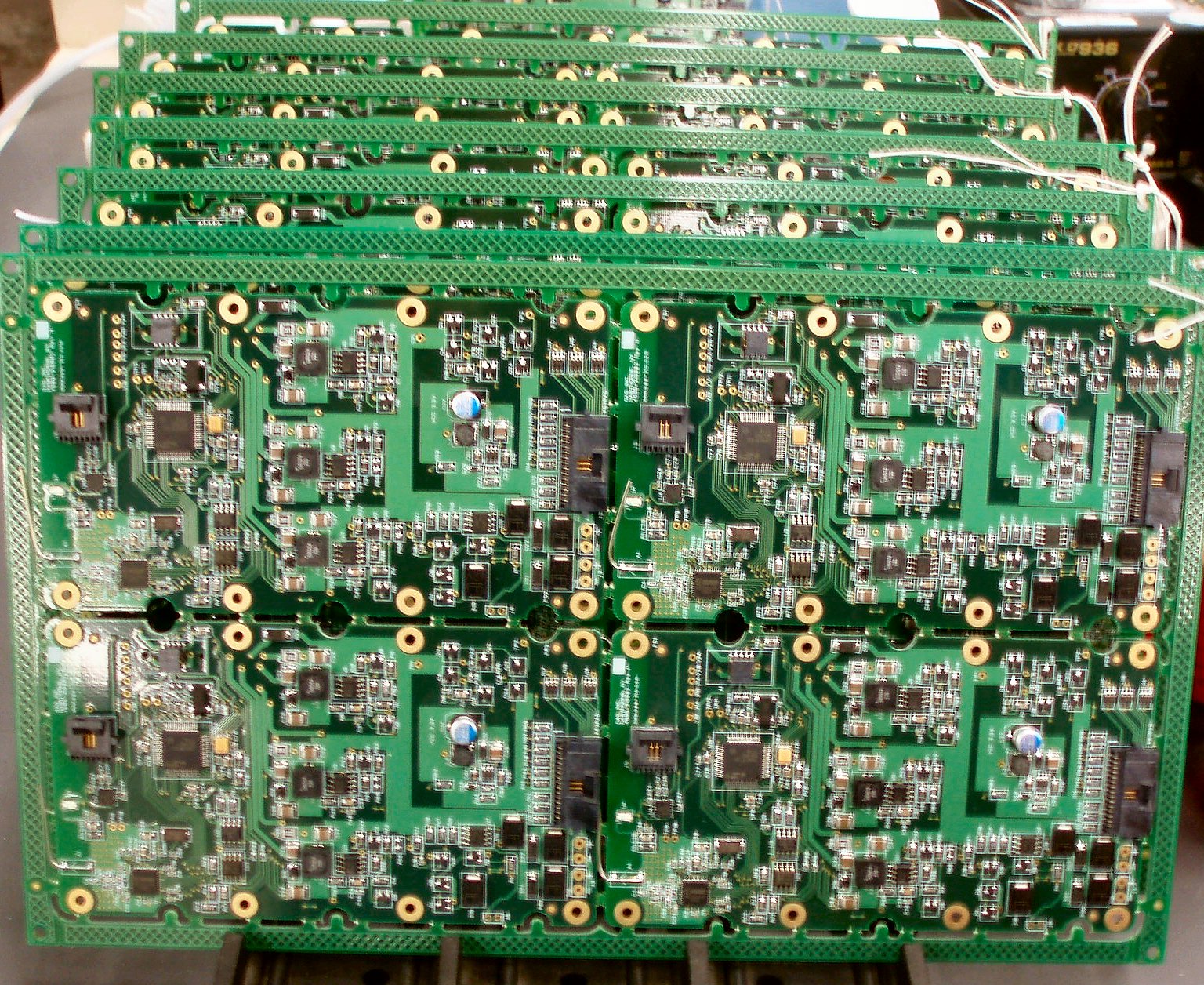

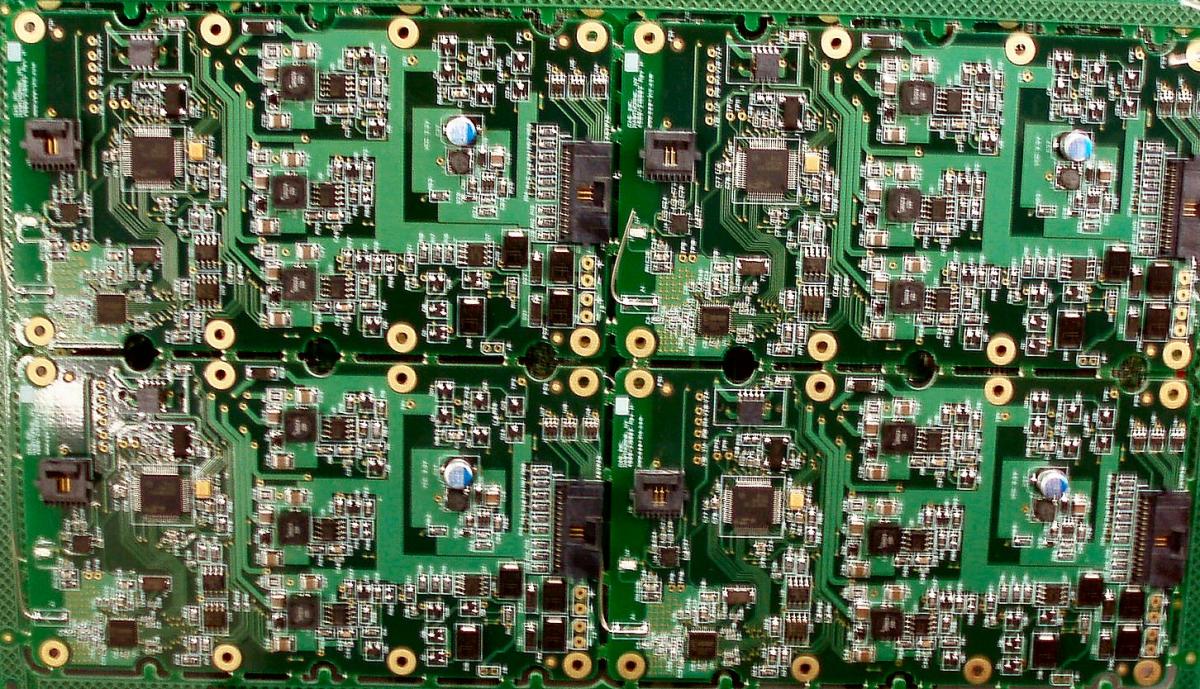

Our cabinets (and systems) are deployed to over 68 radar sites across the United States and will protect the National Airspace System and the freedoms we Americans enjoy. Read more: http://www.vma-llc.com/case%20studies